Processing

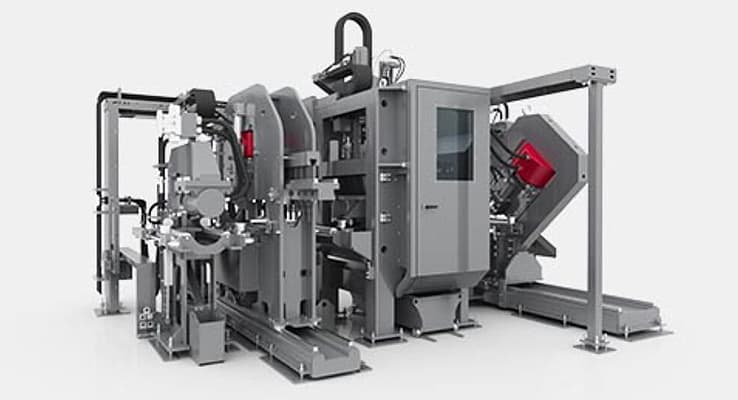

Gulf States Saw & Machine Co. recognizes that no two fabricators are the same. Because the processes and nature of each task are different, this is why it is important to be aware that not all fabricators have exactly the same needs. We have assembled the finest structural fabrication machines that meet your requirements. We can offer the highest quality structural fabrication machines, regardless of your budget!